SHEET METAL AND CUSTOM FABRICATION

The experience of K & I Sheet Metal, Inc. in many industries helps us meet your need to design and fabricate components and systems unique to your operation. With sheet metal as our prime material of construction, our record of custom fabrication includes:

Electrical equipment enclosures

Junction boxes

Conveyor covers

Roof flashing – roof curbs

Corrosion – resistant fume hoods

Barrel hood covers

Motor covers

Hand rails

Elevator door covers

Custom sheet metal projects

And customer safety items such as machine-guards measured, fabricated and installed to comply with OSHA and ADA standards.

Materials in stock include galvanized steel sheet 4’ and 5’ widths, plate, black iron, aluminum, stainless steel, hot-rolled steel, copper, brass and galvanneal all in a variety of gauges.

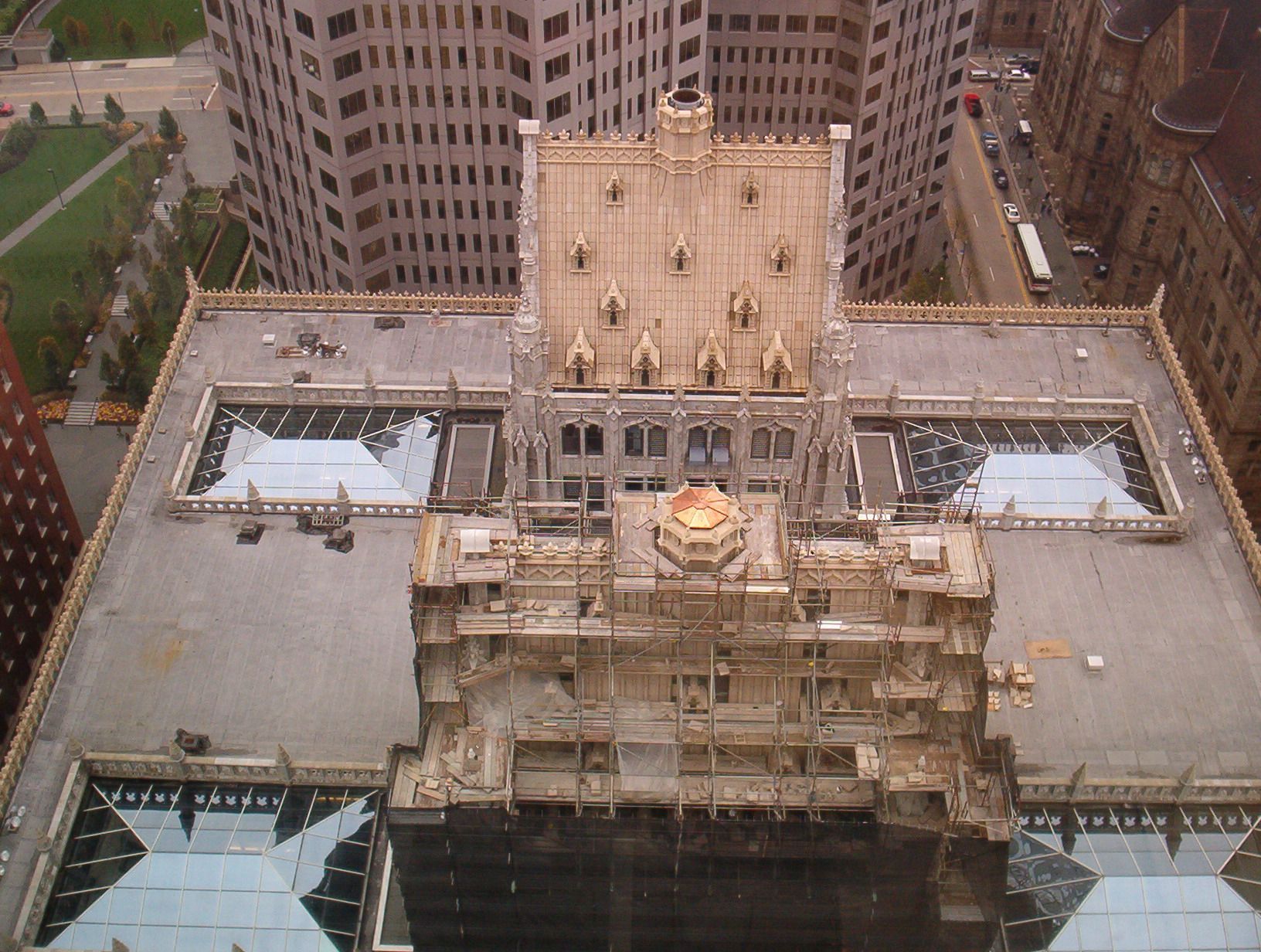

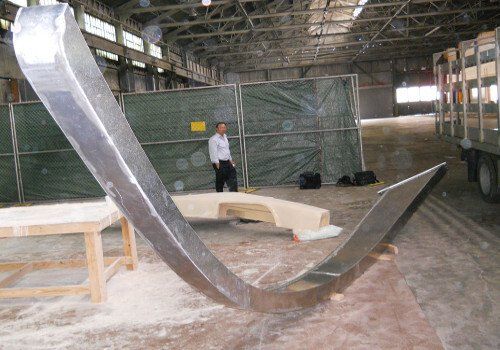

CUSTOM FABRICATING

Photos

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

STANDARD PROCESSES

Include:

Our standard processes are: shearing, bending, rolling, punching, perforating and welding mild steel up to 1/4-inch thick, stainless steel up to 3/16-inch thick. Welding processes are shielded Metal Arch (stick welding), Gas Tungsten Arc (TIG), Gas Metal Arch (MIG), and Carbon Arc, plus plasma arc cutting of carbon steel, stainless steel and other metals up to ½-inch thickness. When required we also provide certified procedures and welders.

12015 © K & I Sheet Metal, Inc. All rights reserved.

PO Box 7848 · 2010 Chapman St. · Pittsburgh, PA 15215 · (412) 781-8111

Website Design by Red Lab Media